The Story of a Fog Catcher Barrel - 130 Years in the Making

As an all estate winery, attention to detail matters. The hands-on experience of farming our own vineyards is invaluable when it comes to making impactful decisions throughout the winemaking process.

Winemaking doesn't follow a recipe; each vintage gives us different expressions of each varietal to work with. While the science of winemaking is the foundation in which we stand upon, the "craft" element is the art of taking our ingenuity, experience and techniques to make a truly special wine.

When it comes to crafting Fog Catcher, our premier Bordeaux blend, understanding the nuances of each varietal is paramount. Our winemaking team selects specific blocks and varietals that show potential early on and guides them through the winemaking process with close attention to detail. Each component ages in separate barrels and only the best barrels make it into the final blend. Aside from the actual fruit we work with, the barrels we use make the largest impact on a finished wine. To understand the importance of the barrel aging process, it helps to understand the craftsmanship that goes into each individual barrel, before it even gets to our winery.

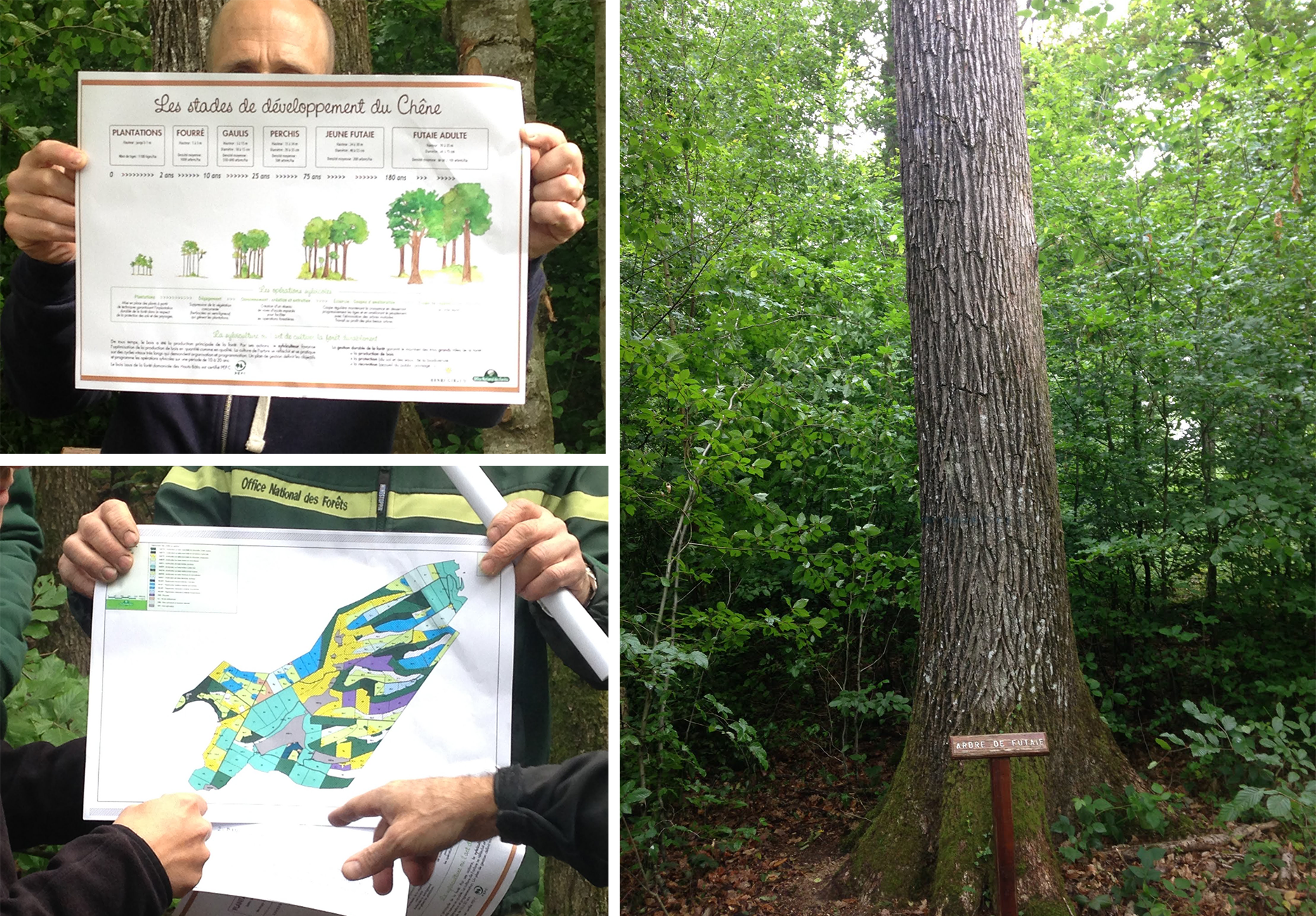

Trees growing in a French Oak forest

Making a fog catcher barrel

Winemakers have used oak barrels for thousands of years to enhance desirable flavors and soften wines as they age. Depending on the type of barrel used, different flavors and qualities will be present in the finished wine. We use all French oak barrels from five main Coopers for our Fog Catcher program.

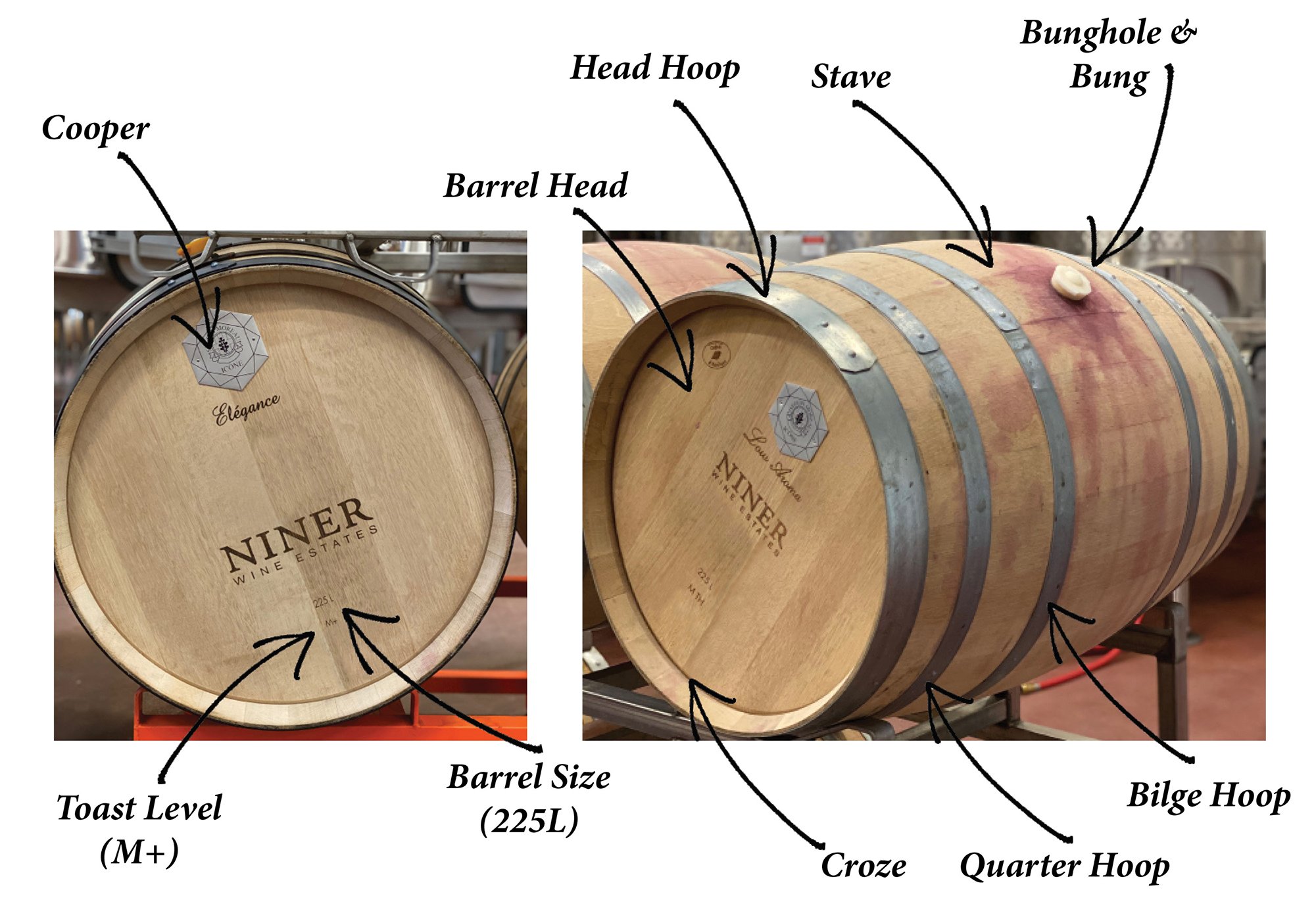

In the barrel-making world, a Cooper is comparable to a winemaker. The Cooper takes the raw ingredients (oak staves) and creates a barrel that serves not only a functional purpose (holding the wine) but also adds structure, tannin and different flavors to a wine. Barrels are not “one-size-fits-all” so this is where the benefits of an estate model come into play. Our winemaking team has learned over time that certain varietals and vineyard blocks thrive under different oak regiments. They work closely with the Cooper to craft barrels with the right attributes to complement each varietal.

Timeline of a Fog Catcher Barrel:

all photos below are from one of our winemaking team's cooper trips

top left: a graph depicting The stages of oak tree growth; bottom: a forest block map outlining areas that are harvested together (similar to vineyards) RIght: An example of a mid-sized oak tree in a french forest

Years 1-125

French oak forests are strictly managed by the federal government as far as what can be harvested and when. French oak trees grow for an average of 125 years before they are cut down and used for barrels. Only the section of the trunk up to the first branch is viable for barrels thus, each tree makes an average of two finished (225L) wine barrels.

from top Left; Large logs stacked at a mill; a sample of a trunk cut frim a tree destined for barrels; logs and staves stacked in a mill yard.

year 126

Once the tree is ready for harvest, it is cut down into large logs. The logs are carefully moved out of the forest so as not to disturb the younger trees and brought to a mill.

Staves stacked onto pallets at a mill yard

years 126-128

At the mill, the logs are cut into roughly 3-foot segments and then split with a wedge to preserve the vertical wood grain. The wood is then sawed into smaller segments called staves. The staves are stacked onto a pallet and moved outside where they will sit for a minimum of two years. During this process called seasoning, rainfall leaches harsh flavors and characteristics out of the oak wood. If the mill is in an area with low rainfall, irrigation systems are set up to keep the wood damp. If not seasoned long enough, these unsavory characteristics would likely be present in the wine. All barrels in our Fog Catcher program are made from wood seasoned anywhere between 3 and 5 years.

Both images show partially assembled barrels in the middle of the firing process. each barrel sits over a flame that softens the wood

year 129

After seasoning, the oak staves go to the Cooper to be made into barrels. The Cooper takes a few things into account when selecting staves for each barrel including; terroir, grain and toast levels:

terroir

Similar to grapes grown in different vineyards, oak tree qualities vary by the forest. The Cooper can choose to combine staves from different forests and regions, adding different flavor elements (similar to blending in winemaking).

GRAIN

The actual grain of the wood adds different elements to the wine. Coarser-grained wood delivers a more robust tannin whereas tighter grained wood leads to a softer tannin and typically more aromas in the wine. A Cooper can choose to make barrels with all coarse-grained staves, all tight grain or a combination for different effects.

Once the Cooper has selected the staves, he assembles them into a hoop and brings them into shape. The staves are still straight when they come to the Cooper so the Cooper “fires” the partially assembled barrel to soften the oak wood and make it more flexible. The Cooper then bends the staves and brings them together to form the final shape.

Barrels being toasted over flames

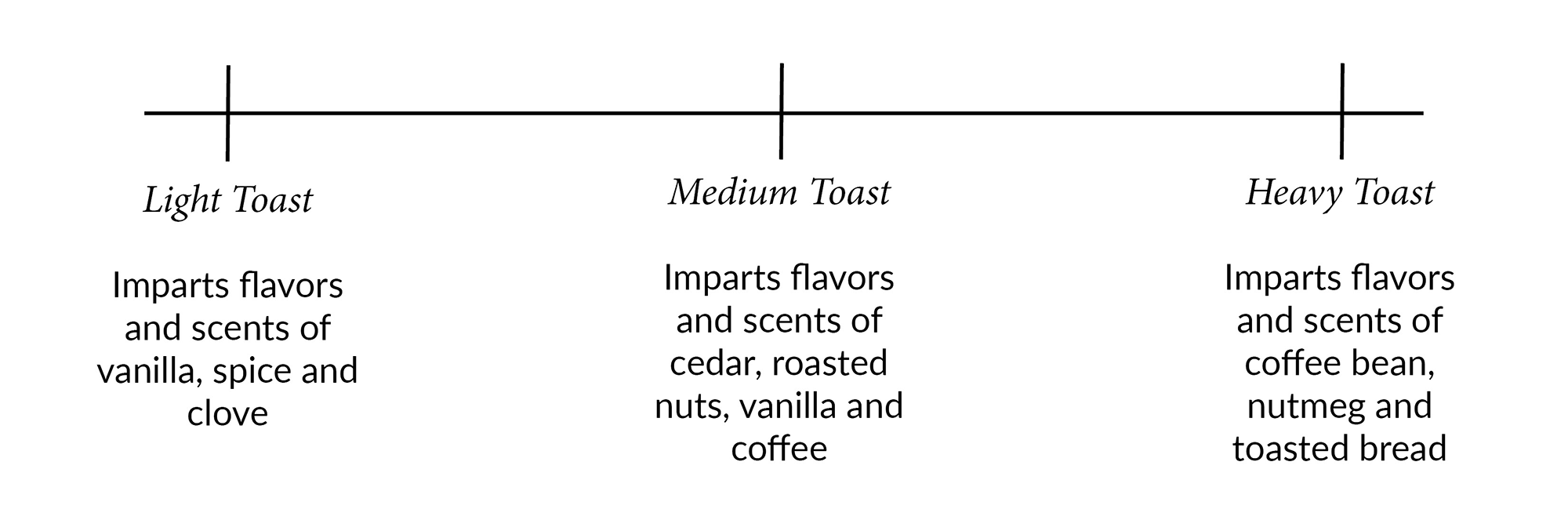

toast

Toasting is one of the most impactful steps of the process. The Cooper toasts the inside of the barrel over a flame to add different flavor characteristics and qualities. The duration of the toasting process and the temperature of the flame affect the flavor impact that the finished barrel will have on the wine.

Now the barrel is ready for finishing touches. The Cooper sands down and cuts a notch (called a croze) on the inside of both ends where the heads will go. The heads are inserted into the croze and the metal hoops are forced into place to tighten the barrel. The Cooper cuts a bunghole into one of the staves and tests the barrel for leaks. It is then sanded and cleaned and starts its journey to our winery.

Anatomy of a Finished Barrel

YEAR 130 - 134

Fast forward to the end of Harvest and all of Fog Catcher's components are now aging in their individual barrels. Over the next 29 months, the wine evolves dramatically and the barrel slowly adds tannin, structure and aromas. Once our winemaking team feels the blend is ready, we bottle it and set it aside in our cellar for a few months of additional aging.

Each fall we celebrate the release of a new vintage of Fog Catcher. After all the time and work that goes into making Fog Catcher, our favorite part is sharing the finished blend with you. Our current vintage, the 2016 Fog Catcher is available for the next few months, until we release the 2017 vintage this fall. Once we release the 2017 vintage, the 2016 Fog Catcher will be moved into our library. Click here to add the 2016 Fog Catcher to your collection »

YEAR 134 - 144

A new oak barrel loses most of its flavor characteristics after just one use. A barrel is considered neutral after three years of use, and it will impart little to no flavors into a wine. We age Fog Catcher in mostly new French oak, meaning after just one use most of the barrels are retired from the Fog Catcher program. For the next 10+ years, these neutral oak barrels play an important role in our winemaking program. Aging certain wines in neutral oak barrels gives us all the benefits of oak aging, without any of the oak flavors. The oak softens otherwise tannic wines while maintaining the fruit qualities of the wines.

2016 FOG CATCHER

45%CABERNET SAUVIGNON, 26% MALBEC, 15% CARMENERE, 14% PETIT VERDOT

The 2016 Fog Catcher represents the best Bordeaux fruit of the vintage. The base of this wine is comprised of our best block of Cabernet Sauvignon at Heart Hill Vineyard co-fermented with a small amount of Petit Verdot. After a year of aging all components separately, our winemaking team runs through a series of blend combinations to determine the final blend composition. They blend the best barrels together and returned the wine to barrel for additional aging. This wine will age well for the next 10+ years and its dark fruit qualities and expressive tannins will only continue to evolve.

Curious about the aging potential of other vintages of Fog Catcher? Our Aging Chart reflects our winemaking team's recommendations for aging and the optimal time to drink a certain vintage. Click here to download »